Many homes rely on older windows that were never designed with insulation in mind. Single-pane glass, thin frames, and worn seals allow heat to escape in cooler months and enter during warmer weather. Today’s replacement window systems are designed to reduce heat loss, limit air leakage, and help maintain more consistent indoor temperatures.

Modern window insulation addresses these issues by combining improved frame construction, insulating glass units, and specific installation methods that seal the window properly within the existing opening, helping homes feel more comfortable year-round while using energy more efficiently. This guide explains how replacement windows are designed and installed with insulation in mind, breaking down the specific elements that contribute to insulation performance.

Table of Contents

How Window Insulation Works

The goal of window insulation is to slow the natural movement of heat and air from warmer areas, such as your home’s interior, to cooler regions, like the exterior of your home. Because the glass and frames sit directly between the indoors and outdoors, windows are a common place for that transfer to occur, making insulation a primary focus in window manufacturing and installation.

Insulated windows use multiple layers of glass with sealed spaces to interrupt the transfer process. Air or gas between panes acts as a barrier that slows heat transfer. Coatings on the glass reflect heat toward its source, helping keep indoor temperatures more stable. At the same time, tightly sealed frames and sashes limit air leakage.

No single component provides insulation on its own. Frame design, glass construction, and sealing methods all work together to reduce heat flow and air movement. Understanding this system-level approach makes it easier to see why modern replacement windows insulate more effectively than older window designs and why each element plays a role in overall performance.

Insulating Elements Built Into Replacement Window Frames

In a replacement window, the frame forms the outer structure that holds the glass in place and connects the window to the wall of the home. Modern replacement window frames use several insulation-focused design features to address these challenges.

| Insulating Element | Description |

| Low-conductivity frame materials | One of the most important insulating features of a window frame is its material. Some materials, like aluminum, allow heat to move through them easily, while others slow it down. Materials, like vinyl and fiberglass, naturally resist the flow of heat, reducing energy loss around the edges of the window, keeping indoor temperatures more stable throughout the year. |

| Multi-chambered frame construction | Many replacement window frames are designed with multiple hollow spaces rather than solid material. These internal chambers trap still air inside the frame. As air slows heat movement, this design creates multiple barriers that reduce the speed at which outdoor temperatures affect the inside of the home. |

| Insulated or reinforced internal cavities | Some window frames include internal cavities that are reinforced or insulated to improve strength while maintaining thermal performance. These internal supports help the frame stay rigid and properly aligned over time, which is important because frames that shift or bend can develop gaps that allow air leakage and reduce insulation effectiveness. |

| Thermal separation within the frame | In certain frame designs, especially those with internal reinforcement, thermal separation is used to limit direct heat flow between the inside and outside portions of the frame. By preventing these surfaces from being in direct contact, thermal separation reduces the amount of heat that can travel straight through the frame. |

| Integrated sealing surfaces that limit air movement | Even a well-insulated frame can lose performance if air is allowed to move through gaps around the window. Modern replacement window frames are designed with built-in sealing surfaces where flexible materials compress when the window is closed, creating a tight barrier that blocks air movement and helps prevent drafts and uneven temperatures. |

Schedule a Free Consultation

Get a free home window inspection, talk with one of our design consultants to get product recommendations, and learn about special offers and financing.

Insulating Elements in Replacement Window Glass

Glass makes up most of the window opening, which means it plays a major role in how much heat enters or leaves the home. Modern replacement windows use insulating glass units that combine two or three pane layers, sealed spaces, and coatings to slow heat transfer and reduce temperature swings near the window.

| Insulating Element | Description |

| Multiple panes of glass | Replacement windows use different numbers of glass panes to control insulation. Single-pane windows consist of one sheet of glass and provide very little insulation. Double-pane windows add a second layer of glass with a sealed space between them, which significantly slows heat transfer. Triple-pane windows add a third layer and an additional sealed space, creating even more barriers that heat must pass through. Each added pane improves insulation and helps keep the interior glass surface closer to room temperature. |

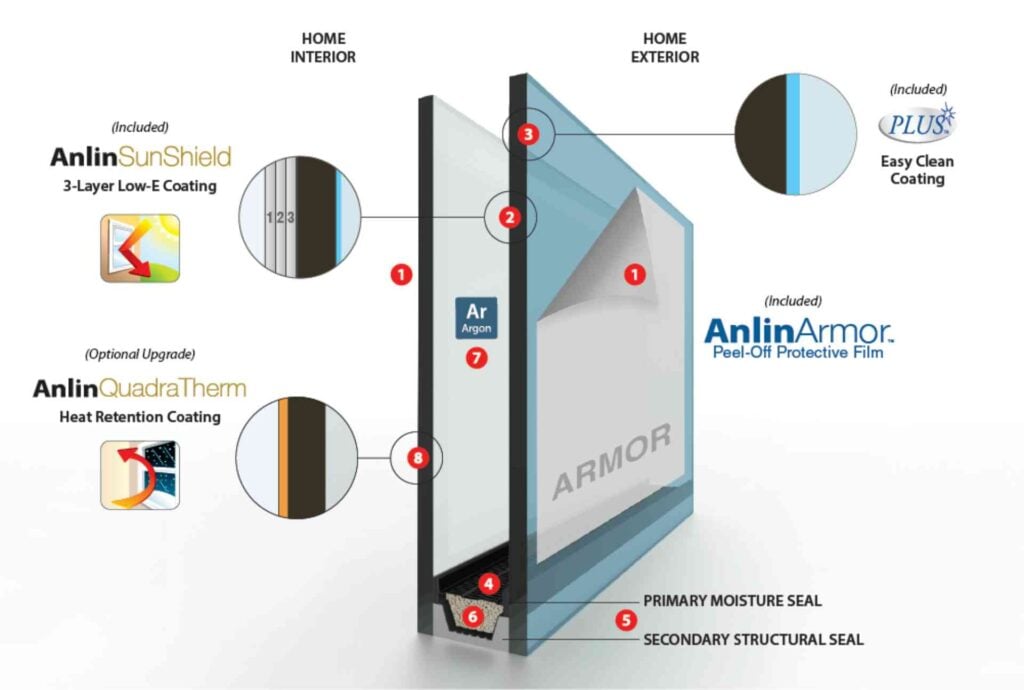

| Sealed spaces between glass panes | The space between panes is sealed to prevent air movement. When air is trapped and kept still, it slows the movement of heat and acts as insulation. Some insulating glass units use sealed air-filled spaces, while most enhance insulation by filling part or all of the space with insulating gases. In all cases, insulation depends on keeping the space sealed so the contents cannot circulate. |

| Insulating gases that enhance air insulation | Many modern windows use gases such as argon or krypton inside the sealed space between panes to improve insulation. These gases are denser than air, which allows them to slow heat movement more effectively. Argon is commonly used in standard insulating glass units, while krypton is often used in narrower spaces where higher insulation is needed without increasing glass thickness. |

| Low-emissivity glass coatings | Insulating window glass often includes a thin, nearly invisible coating that reflects heat instead of allowing it to pass freely through the glass. In cooler conditions, Low-E coating helps reflect indoor heat into the room. In warmer conditions, it reduces heat entering from outside. This improves insulation while still allowing natural light to pass through the window. |

| Spacer systems that maintain insulation at the edges | Spacer systems hold the glass panes apart and help maintain the sealed insulating space between them. These spacers also reduce heat transfer at the edges of the glass, which is a common weak point in older window designs. Modern spacers are designed to support both insulation and long-term durability. |

| Long-term seal integrity | All insulating glass technologies rely on a durable seal that keeps air or insulating gas inside the glass unit and prevents moisture from entering. As long as this seal remains intact, the glass continues to insulate effectively. When the seal fails, insulation performance drops, making seal durability a critical part of long-term window performance. |

Installation Techniques That Preserve Insulation in Replacement Windows

Insulating windows are only as effective as their installation. Even high-quality frames and glass can lose much of their insulating value if air and moisture are allowed to move around the window opening. The best installers use proprietary installation approaches designed to protect insulation, manage water, and keep the window sealed long after installation day.

| Insulating Element | Description |

| Creating a sealed, protected window opening | Before a replacement window is in place, experienced installers prepare the opening so it can support long-term insulation. This includes applying protective barriers around the opening that block moisture and air from reaching the surrounding structure. These layers act as a first line of defense, helping prevent leaks that can compromise insulation over time. |

| Managing water at the base of the window | Water intrusion is one of the fastest ways insulation performance breaks down. High-quality installation methods include systems at the bottom of the window opening that collect and redirect water away from the wall if it gets behind the exterior surface. By safely channeling water outward, these systems protect insulation, framing, and interior finishes. |

| Using layered flashing to deflect moisture | Rather than relying on a single seal, the best installers use multiple overlapping layers around the window opening. These layers work together to guide water away from the window, similar to how roofing materials shed rain. This layered approach reduces the risk of moisture reaching areas where it could degrade insulation or cause air leaks. |

| Sealing with durable, flexible materials | To preserve insulation, installers use sealants designed to remain flexible as materials naturally expand and contract. These sealants help maintain a tight seal between the window and the wall, limiting air movement and preventing gaps from forming over time. |

| Insulating and sealing the perimeter gap | After the window is set, the space between the window frame and the surrounding opening is insulated and sealed. Filling this gap prevents drafts and heat loss around the edges of the window, allowing the insulating features built into the frame and glass to perform as intended. |

| Verifying fit, alignment, and long-term performance | Proper alignment ensures the window closes tightly and evenly. When the window operates smoothly and seals correctly, its built-in insulation features remain effective. The best installers take the time to confirm that everything is properly sealed, insulated, and functioning as a complete system. |

Common Insulation Failures in Window Systems

Window insulation problems do not always come from a single missing feature. In many cases, insulation performance declines because different parts of the window system stop working together over time. These failures can occur even in windows that appear intact, making comfort issues harder to trace without understanding how insulation breaks down.

- Insulation that depends on a single component. Windows that rely heavily on one insulating feature often underperform because effective insulation requires the frame, glass, and sealing to work together as a complete system.

- Heat loss at the edges of the window. Even when the center of the glass insulates well, heat commonly escapes at the edges where the glass, frame, and spacer meet, creating cold zones or drafty areas around the perimeter of the window.

- Gradual loss of airtightness. Over time, normal movement, material wear, and repeated use can reduce how tightly a window seals, allowing air to move through small gaps and lowering insulation performance even if the window still operates smoothly.

- Unintended heat paths through the frame. Some window designs allow heat to travel through the frame by bypassing insulating air spaces, which reduces overall insulation even when other components perform as intended.

- Moisture-related insulation degradation. Repeated exposure to moisture around the window opening can weaken surrounding materials and seals, leading to air leakage and a gradual decline in insulation performance.

Signs It’s Time to Upgrade to Insulating Replacement Windows

Insulation problems are often easiest to recognize through everyday comfort issues rather than visible damage. Windows that no longer insulate effectively create various hidden costs that you’ll want to avoid. Signs tend to show up in how rooms feel, how the home holds temperature, and how the window system behaves over time.

- Drafts near closed windows. Feeling moving air near a closed window usually indicates air leakage that allows heat to escape or enter freely.

- Glass that feels cold or hot to the touch. Interior glass surfaces that feel noticeably cold in winter or warm in summer suggest that heat is transferring easily through the window.

- Rooms that are harder to heat or cool. Rooms that struggle to maintain a comfortable temperature often have windows that allow significant heat loss or gain.

- Condensation is forming on the interior glass. Frequent condensation on the inside surface of the glass can indicate poor insulation and cold interior glass temperatures.

- Fog or moisture between glass panes. Moisture trapped between panes usually points to a failed seal, which reduces the insulating ability of the glass unit.

- Noticeable temperature differences near windows. Standing close to a window and feeling a temperature change compared to the rest of the room is a common sign of insulation loss.

- Higher heating or cooling use than expected. Windows that no longer insulate well can force heating and cooling systems to work harder to maintain indoor comfort.

- Outside noise is becoming more noticeable indoors. While not solely an insulation issue, increased noise often accompanies poor sealing and reduced insulating performance.

- Windows that rattle or shift in the frame. Movement within the frame can compromise seals and allow air leakage that reduces insulation.

- Older window designs that predate modern insulation standards. Single-pane windows and early double-pane windows often lack the insulating frames, glass, and sealing systems found in modern replacement windows.

Get More Comfort From Properly Insulating Replacement Windows

Insulating windows perform best when the entire system is designed and installed correctly. That means choosing high-quality replacement windows and working with an installer who understands how frames, glass, and installation methods all affect insulation.

Lake Washington Windows and Doors helps Seattle-area homeowners upgrade to insulating vinyl and fiberglass replacement windows from trusted manufacturers like Milgard and Anlin Windows. Our team focuses on professional replacement installation that protects insulation, limits air and moisture intrusion, and supports long-term performance

If your home is experiencing drafts, cold glass, or uneven room temperatures, schedule a complimentary in-home window consultation to explore insulating replacement window options that can improve comfort throughout your home.